Akzemin Teknik Makina

DESCRIPTION

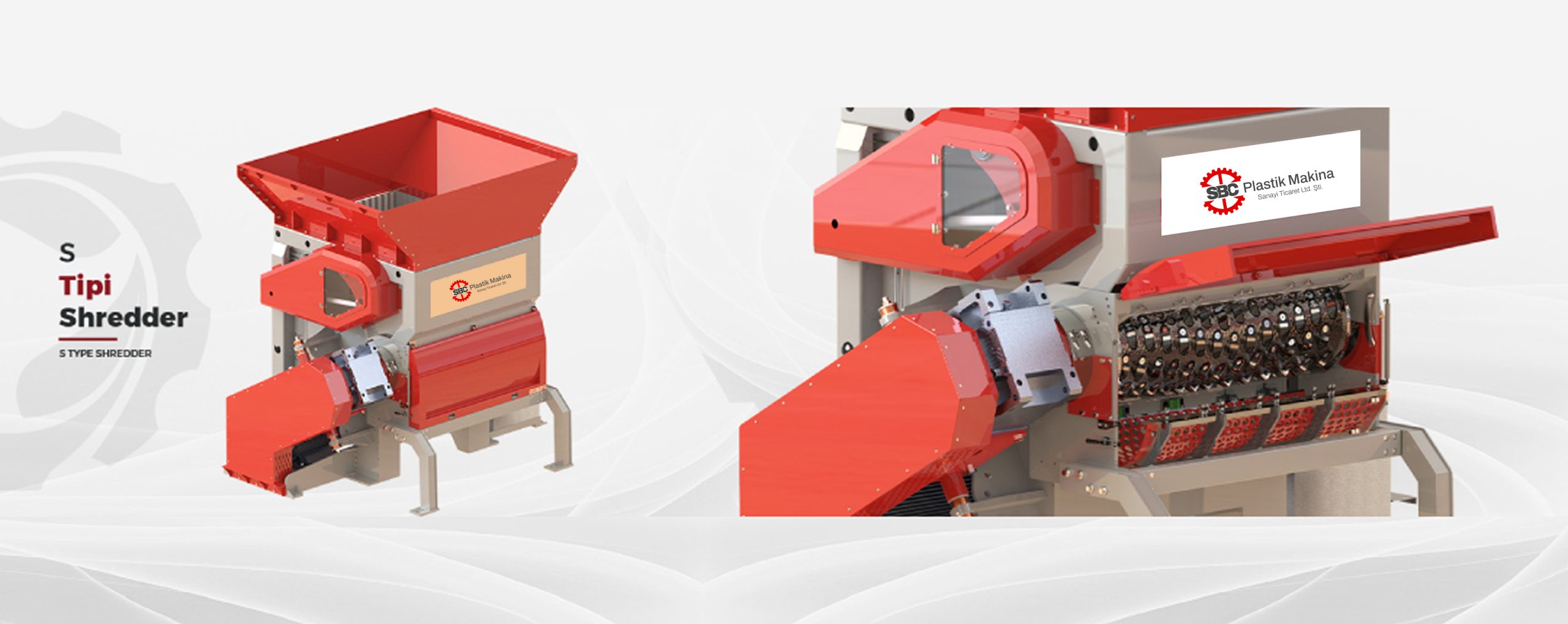

S type Shredders are developed for the breakdown of industrial wastes, household wastes and agricultural wastes. It is used for reducing the size of plastic wastes such as pipes, wedges, crates, pallets, film rolls, bale films, sacks and wastes such as cardboard, paper, textiles.Novotel. According to the principle of operation, it is absolutely not affected by the coercive effects of the material such as thickness, hardness, density.

With the printing unit driven by hydraulic power, the material to be broken down is pressed on the rotor. In this way, the material to be broken down is pressed into the blades and high efficiency is obtained from the machine. Thanks to the angled shredding chamber, it has a design especially suitable for shredding materials with low bulk density.

The printing time, printing shape, rotor speed are controlled by the PLC system and the correct parameters are loaded into the system by selecting the appropriate one from 3 different recipes according to the type of material processed. The recipe parameters can be changed according to the different wastes processed.

Shredder rotors are produced with water cooling in order to prevent the processed plastics from being affected by the temperature generated during the shredding process. Anti-abrasion protection is applied to the rotor surface against the corrosive effects of plastic. In addition, according to the type and pollution of the processed plastic, Hardox anti-wear armor can be applied on the rotor.

Made of special alloy steel material, it has low operating costs thanks to fixed and rotating blades that provide multiple use possibilities. Thanks to the fixing of the rotating blades on the rotor with special connection cartridges to the rotor, blade replacement has been facilitated and damage to the rotor has been prevented. The blade sizes, the blade model and the number of blades on the rotor are determined according to the type of plastic to be processed and the pollution condition. Different types of sieves are produced according to the type of material to be processed, and special alloy sieve material is used taking into account the corrosive effects of the material.

The bearings are located in completely isolated, water-cooled bearings, thus preventing material transfer to the bearings and extending the service life. Thanks to heavy-duty gearboxes and shock-absorbing wedges, the dynamic load generated during shredding is prevented from damaging the machine. Thanks to the inverter-controlled motors, energy efficiency has been increased to the maximum level.