Akzemin Teknik Makina

Description

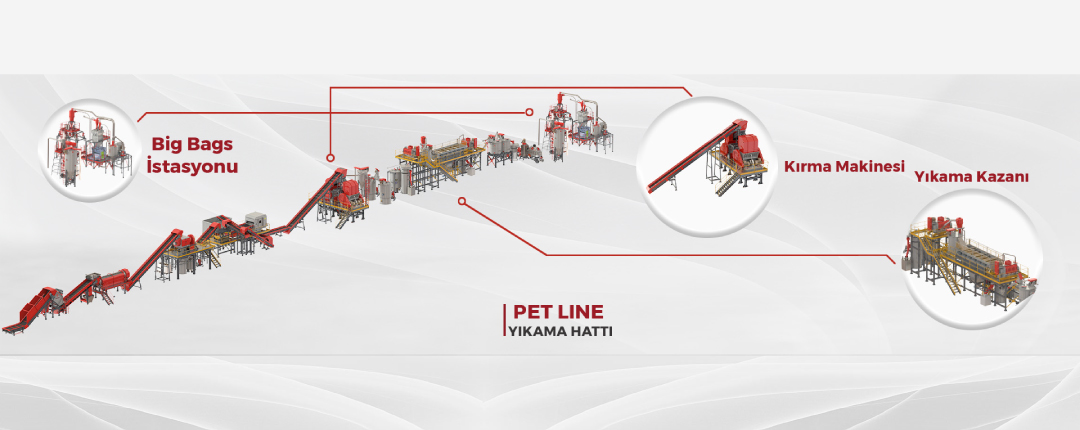

PET WASHING LINES

PET burrs are lines where plastic wastes such as soft drink bottles, food containers, sheets made of polyethylene Terephthalate (PET) polymer are recycled and PET burrs are produced.

PET burrs produced in PET Washing Lines are used in the production of yarn, fabric, fiber or packaging material. In addition, these burrs produced by our PET Washing Lines can come into contact with food by using suitable granule extruders, granules suitable for producing products can be obtained.

PET Washing Lines cover Pre–Washing and Separation, Size Reduction, Flotation – Immersion, Cold and Hot Washing, Label Separation and Drying processes.

In the Pre-washing and Separation section, PET wastes are subjected to the pre-washing process and are cleaned from superficial pollutants at the first stage. In the separation section, PET bottles are separated manually. Optionally, polymer and color separation can be performed without touching by using fully automatic separation systems.

PET materials subjected to Pre-Washing are dimensioned by the Size Reduction process and transferred to the Washing department. In the washing section, cleaning of the material is provided with Washing Centrifuges, Flotation – Immersion Tanks and Chemical Hot Washing. After the Washing and Drying section, PET burrs are optionally passed through the Label Separation system and separated from possible label residues.

The lines are designed according to the pollution condition and capacity of the material.