Akzemin Teknik Makina

Description

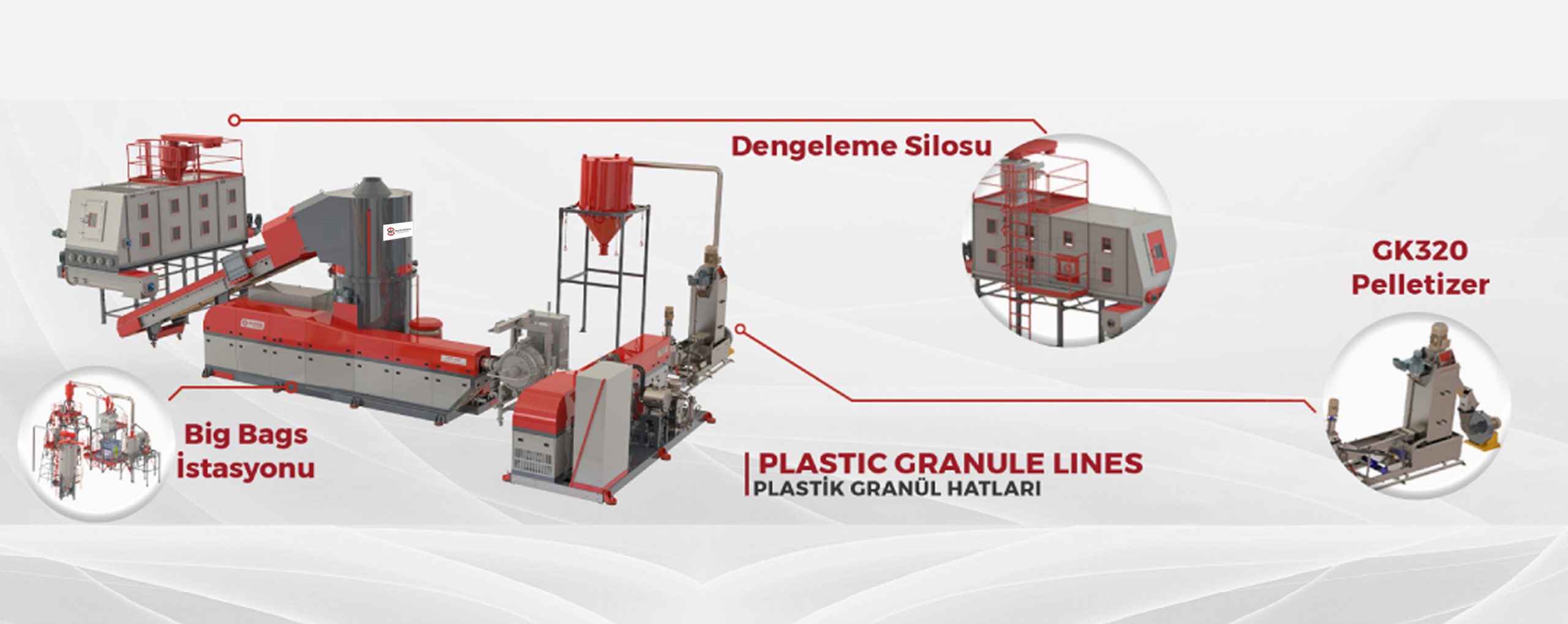

PLASTIC GRANULE LINES (Th–PP–PS–ABS)

Polyethylene (PE), Polypropylene (PP), Polystyrene (PS) and Acrylonitrile Butadiene Styrene (ABS) are the lines used for granulating wastes in film, hard or foam form.Thenpolyethylene (PE), Polypropylene (PP), Polystyrene (PS) and Acrylonitrile Butadiene Styrene (ABS) types.

The machines that make up the Plastic Granule Lines and the technical characteristics of the machines are selected according to the form, shape, moisture content and hourly production capacity of the plastic to be recycled.

Size reduction may be required according to the shape and dimensions of the scrap plastics to be processed in the granule lines. The size reduction equipment to be used is determined according to the shape and shape of the material. While Extruder with CRT Shredder, which can perform both size reduction and extrusion process in one stage, can be preferred, granule production can be completed by using Granule Extruders after the size reduction process is performed with Shredder or Crushing Machine.

If currently fragmented plastics want to be granulated, they are fed directly to the Extruder without using any size reduction equipment.

At the end of the extrusion process, the melt plastic passes through a precise filtration process and is completely automatically cut into granule form on the Granule Cutting Machine. The granules produced are transferred to the Granule Storage Silo or Big Bag Filling Station by pneumatic transfer in accordance with the production capacity of the Recycling Line.