Akzemin Teknik Makina

Description

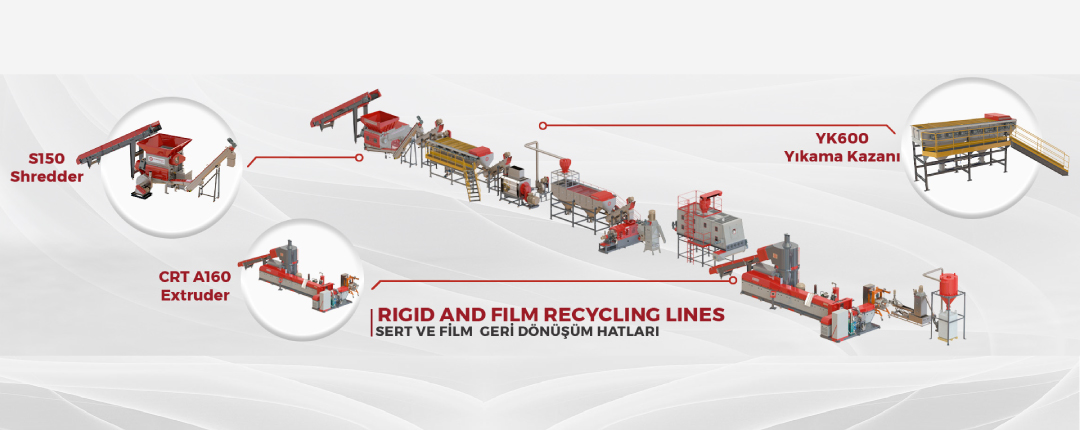

Polyethylene (LLDPE, LDPE, HDPE) and Polypropylene (PP) are the lines used for recycling scrap plastics. These lines are one of the most preferred lines in the recycling industry because they are suitable for recycling dirty waste plastics in hard and film form.

The technical characteristics of the machines and machines that make up the Rigid and Film Recycling lines are selected according to the pollution intensity of the plastic to be recycled, the types of pollutants and the hourly production capacity.

According to its form, plastics that are separated as hard or film are broken down with a Shredder at the first stage of the Recycling Line. The broken down plastics are transferred to the Washing department untouched with the appropriate transport unit.

Cleaning of waste plastics and heavy water pollutants (heavy plastics such as PET, PVC, glass, metal bottle caps, iron coins, etc.) by using a sufficient amount of Washing Centrifuges, Flotation Immersion Boilers and Turbo Washing Centrifuges according to the pollutant density and pollutant types in the washing department.) it is automatically parsed. Cleaned plastics are dewatered in a Film Crimping Machine, Turbo Drying Centrifuge or Dynamic Drying Centrifuge according to their forms. The shredded, washed and dehydrated plastics are transferred to the Balancing Silo to be transferred to the granular extrusion process.

In the Granule Extrusion process, plastics are converted into reusable recycled granules. With the fully automatic, PLC controlled CRT Condenser Extruder, plastics are subjected to both condensation and extrusion process in one stage. At the end of the extrusion process, the melt plastic passes through a precise filtration process and is completely automatically cut into granule form on the Granule Cutting Machine. The granules produced are transferred to the Granule Storage Silo or Big Bag Filling Station by pneumatic transfer in accordance with the production capacity of the Recycling Line.